Preparing Offset Plates: How Do We Ensure Perfect Printing of Your Packaging?

Preparing offset plates is one of the most critical stages in the packaging printing process. At this stage, your design transitions from a digital format to a physical one, ready to apply ink to cardboard. How does this process work, and why is it so crucial for the final result? In this article, we’ll explain step by step how offset plate preparation works and its impact on the quality of your packaging

What Are Offset Plates, and Why Are They So Important?

Offset plates are matrices that transfer your design onto paper or cardboard in the offset printing process. They ensure colors, details, and print quality are reproduced with maximum precision. Each color in offset printing requires a separate plate—for example, in the standard CMYK system, we prepare four plates (for cyan, magenta, yellow, and black).

Offset plates form the foundation of quality—if prepared perfectly, the final packaging will look exactly as you envisioned. Errors at this stage can affect the entire print run.

How Does the Plate Preparation Process Work at Koopress?

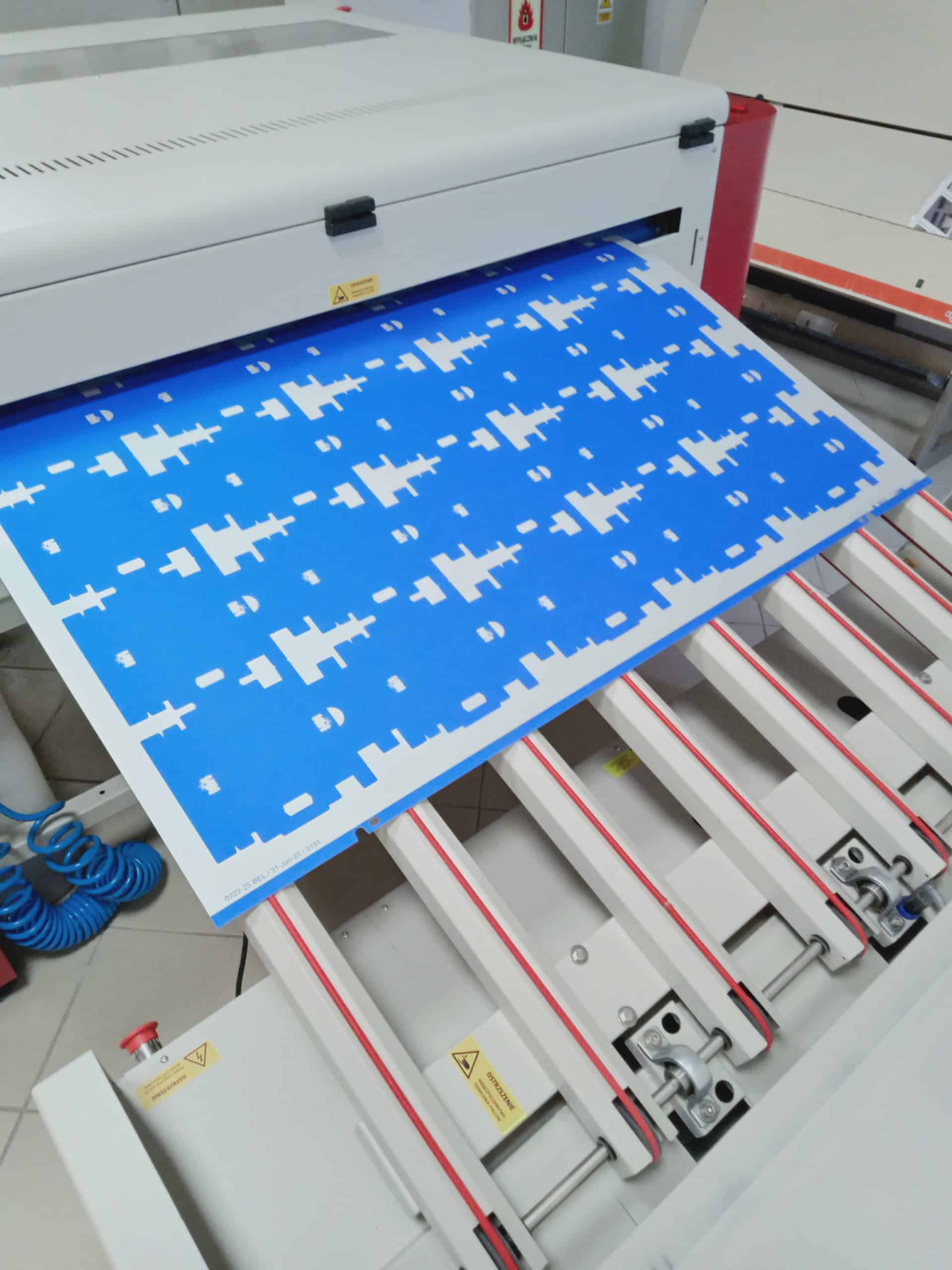

At Koopress, we use CTP (Computer-to-Plate) technology, meaning the plates are exposed directly from a digital file—without the need for film. This eliminates the risk of errors and ensures the highest print quality.

Stages of Offset Plate Preparation:

- File Review and Color Separatio

- Our DTP specialists analyze graphic files, ensuring they meet print requirements.

- Colors are separated into individual CMYK channels or additional colors (Pantone).

- We check for proper bleeds, screen ruling, and tonal transitions that may need adjustment.

- Plate Exposure Using CTP Technology

- Aluminum plates are coated with a photosensitive emulsion and precisely exposed with a laser, ensuring excellent detail reproduction.

- This process eliminates the risks associated with traditional exposure methods.

- Quality Control of Plates

- Each plate undergoes a thorough inspection to ensure no defects, such as missing raster points or contaminants.

- Plates are marked and prepared for mounting on the printing press.

Why Is Offset Plate Preparation Important for You as a Client?

1. Precise Reproduction of Your Design

If you care about the perfect color representation of your brand and sharp details, the preparation stage determines how these elements will appear on the final packaging.

2. Print Consistency and Repeatability

Properly prepared plates ensure that every batch of packaging is identical. Whether printing 1,000 or 100,000 units, the quality remains consistent.

3. Error Elimination Before Printing

Errors identified during plate preparation can still be corrected. If they reach the printing stage, fixes become costly and time-consuming.

Practical Tips for Clients – How to Prepare Files for Offset Printing:

To achieve the best print results, consider these key aspects:

✔ Prepare files in CMYK – RGB colors are not suitable for printing. If using Pantone colors, inform us in advance.

✔ Ensure proper resolution – Graphics should have at least 300 dpi for sharp details.

✔ Add bleeds and safety margins – We recommend 3-5 mm bleeds to avoid issues with trimming.

✔ Verify fonts and lines – Convert text to outlines, and ensure lines are no thinner than 0.25 pt.

Expert Opinion: Błażej, DTP Specialist at Koopress

“Offset plate preparation is a stage where there’s no room for errors. Precision is key—if a plate is poorly prepared, it impacts the entire print run. That’s why at Koopress, we focus on every detail, use advanced control systems, and always consult with clients to achieve the best results.”

Why Choose Koopress?

At Koopress, we use the latest printing technologies and precise methods for offset plate preparation. This guarantees that your packaging will look exactly as you expect—without surprises or compromises.

✔ We ensure top-quality printing – Modern CTP technology minimizes errors. ✔ We prioritize quality control – Each plate is meticulously inspected before printing. ✔ We offer expert guidance – Our DTP specialists help optimize files and select the best solutions.

Have questions? Want to order packaging with flawless printing? Contact us—we’re here to help at every stage of the process!